Normec Foodcare Online

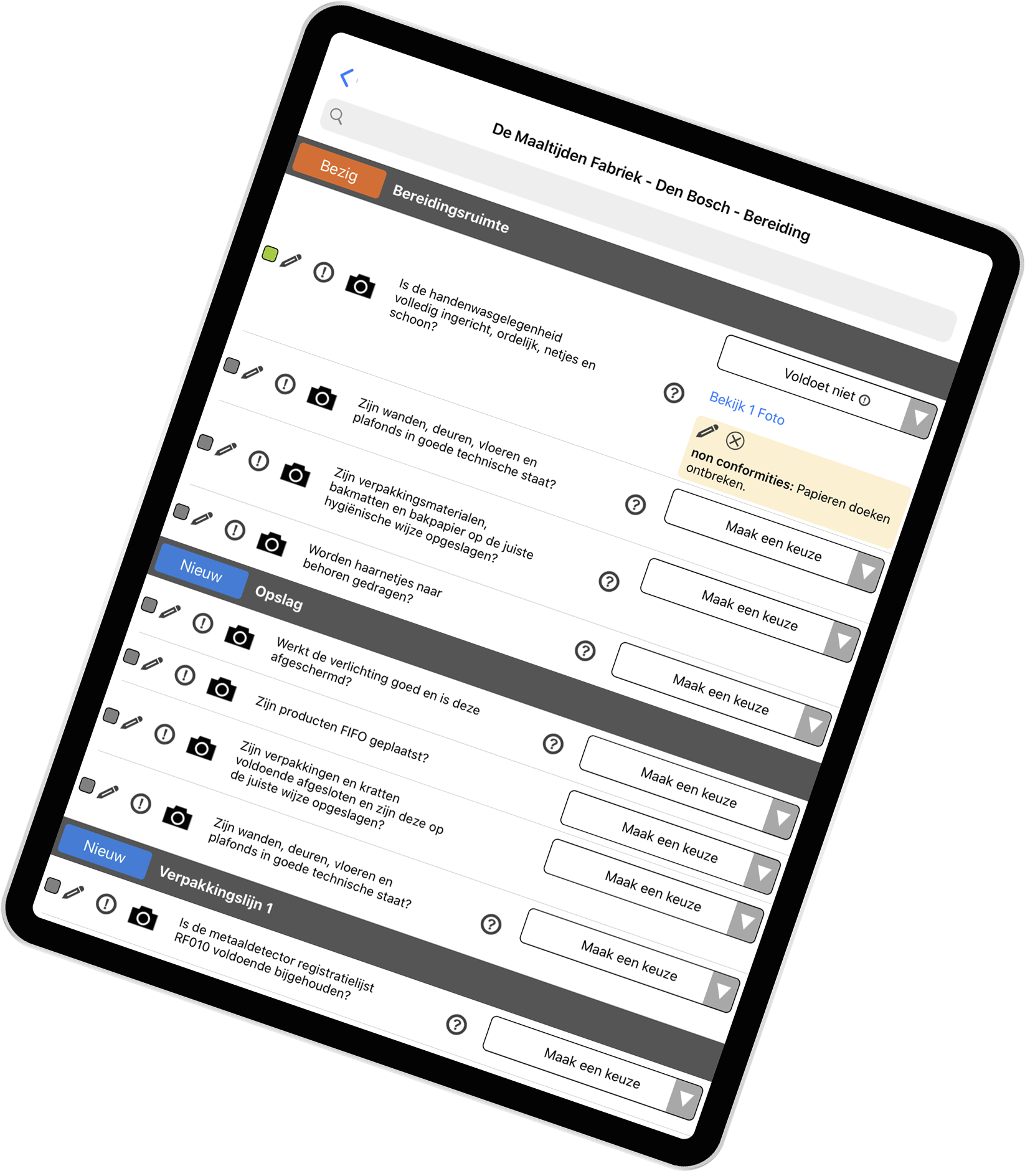

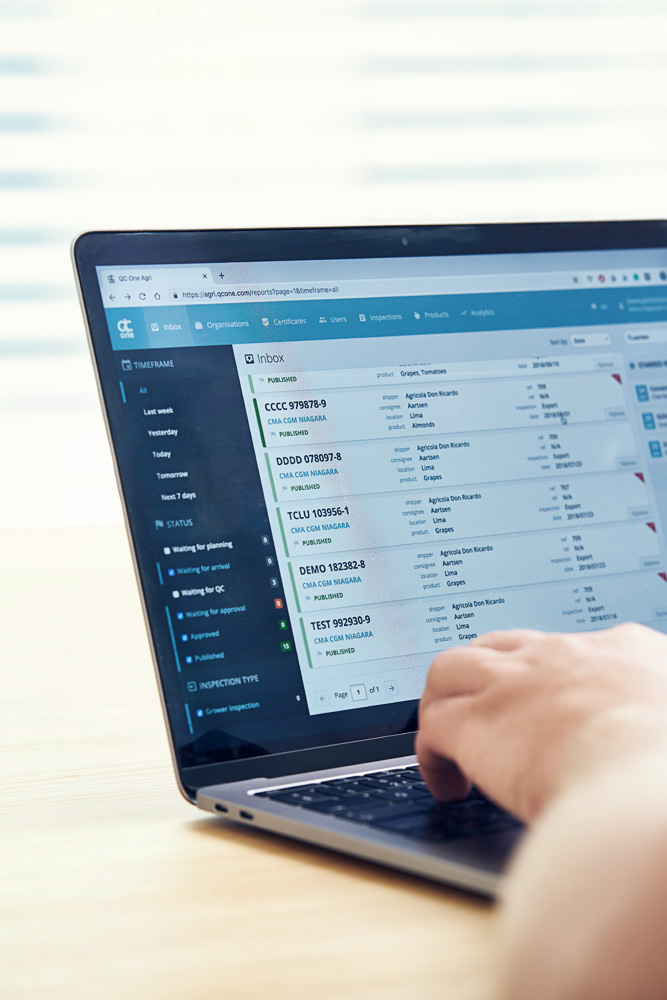

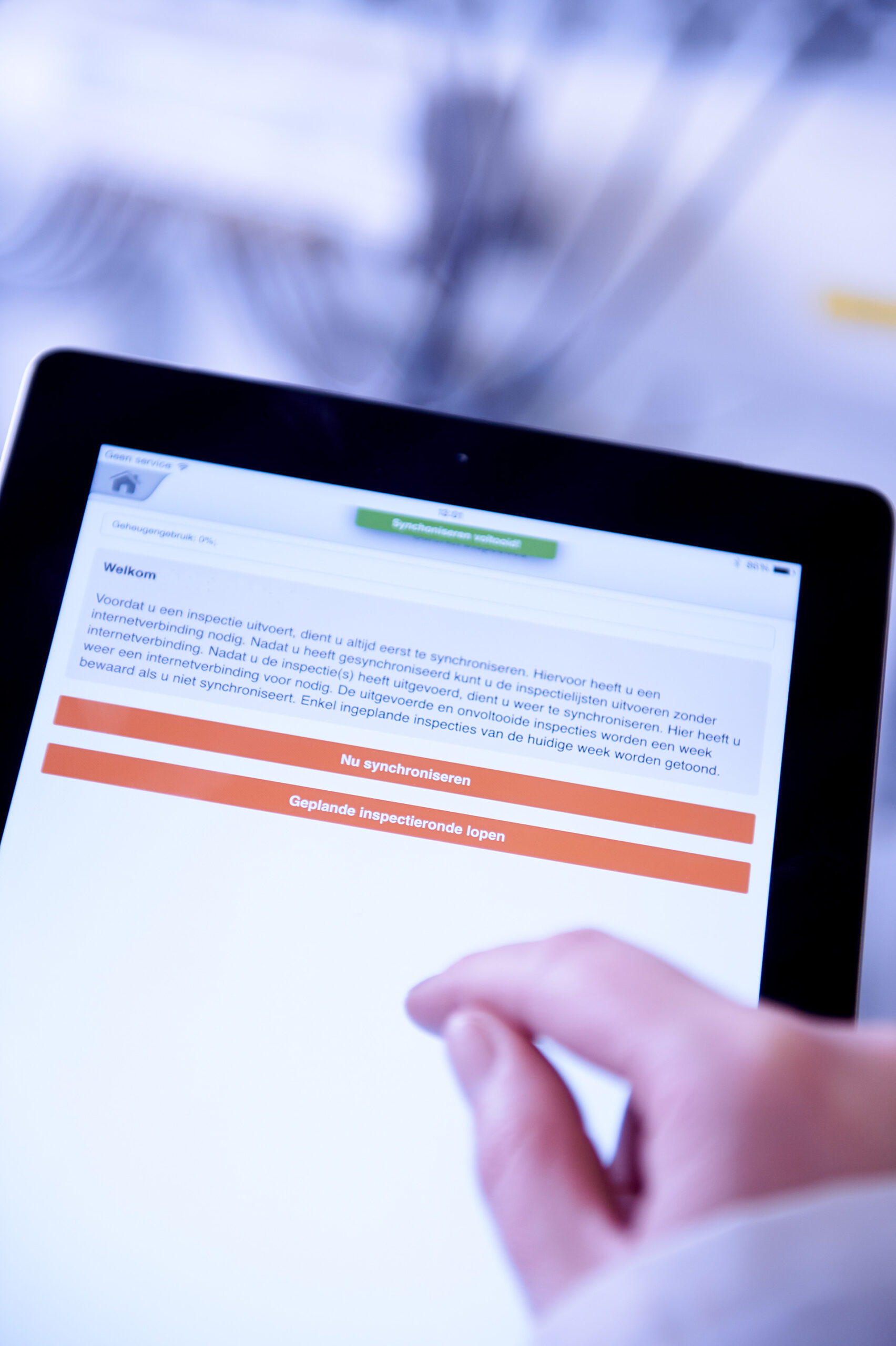

QA Software

Do you want to safeguard your quality issues faster, more efficiently and more effectively? Our online all-in-one QA software has been developed by specialists with a wealth of knowledge and experience in food safety and quality assurance.

- Improve your quality assurance

- Work faster and more efficiently

- Always maintain oversight and control